BSL – LONGITUDINAL WELDING EQUIPMENT

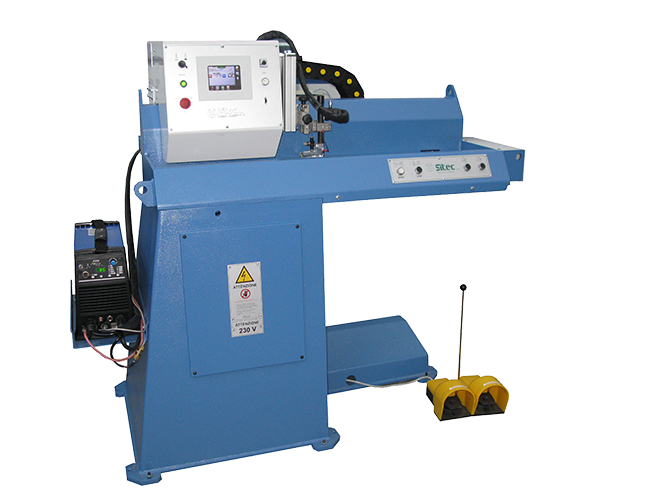

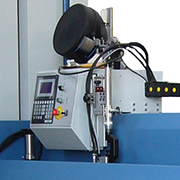

State-of-the art equipment for longitudinal welding of tubes and sheets with different welding process: Tig, Plasma, Laser, Mig-Mag and Submerged Arc. It is equipped with a copper support resisting to wear and tear and heat and with a series of pressing plates in brass alloy that lock the pieces. Pieces with thickness from 0.5 up to 10 mm and lengths which may go from 30 to 8000 mm are joined together thanks to the sturdiness and high precision of the mechanical processing. The BSL series is, in turn, divided into four main categories: standard, liftable, for inside welding and automatic. The standard type is equipped with a supporting rod in copper support at a settled height from the ground and it may have a lifting unit being operated by rollers. What distinguishes the liftable units from the standard ones is that the supporting rod and the bar holding the external pressing plates can be adjusted in height, so that the equipment can be adjusted according to the diameter of the tube being welded. In the lower part of the machine there’s a set of rollers. The BSL series for inside welding is suitable for inside welding of large tubes or sheet metal as its main bar and the torch unit are positioned inside the tube. The automatic machine have the automatic closing cycle of the particular, therefore the operator has only to perform the operations of loading and unloading.

Standard equipments for longitudinal welding of tubes and sheets with different welding process: Tig, Plasma, Laser, Mig-Mag and Submerged Arc. They are equipped with a copper support resisting to wear and tear and heat and with a series of pressing plates in brass alloy that lock the pieces. Pieces with thickness from 0.5 up to 10 mm and lengths which may go from 30 to 3000 mm are joined together thanks to the sturdiness and high precision of the mechanical processing. The BSL STANDARD series is equipped with a supporting rod in copper settled a fixed height from the ground and it may have a lifting unit being operated by rollers to facilitate preliminary closure and loading/unloading of the pieces.

Equipments for inside longitudinal welding of tubes and sheets with different welding process: Tig, Plasma, Laser, Mig-Mag and Submerged Arc. They are equipped with a copper support resisting to wear and tear and heat and with a series of pressing plates in brass alloy that lock the pieces. Pieces with thickness from 0.5 up to 10 mm and lengths which may go from 30 to 8000 mm are joined together thanks to the sturdiness and high precision of the mechanical processing. The BSL series for INSIDE WELDING is suitable for inside welding The BSL series for inside welding is suitable for inside welding of large tubes or sheet metal as its main bar and the torch unit are positioned inside the tube.

Liftable equipments for longitudinal welding of tubes and sheets with different welding process: Tig, Plasma, Laser, Mig-Mag and Submerged Arc. They are equipped with a copper support resisting to wear and tear and heat and with a series of pressing plates in brass alloy that lock the pieces. Pieces with thickness from 0.5 up to 10 mm and lengths which may go from 30 to 3000 mm are joined together thanks to the sturdiness and high precision of the mechanical processing. In BSL LIFTABLE series the supporting rod in copper and the bar holding the external pressing plate can move vertically to adjust the unit according to the diameter of the tube to weld. In the lower part of the machine there’s a set of rollers to ensure smooth closure of pipes’ edges and loading/unloading of the pieces.

Automatic equipments for longitudinal welding of tubes and sheets with different welding process: Tig, Plasma, Laser, Mig-Mag and Submerged Arc. They are equipped with a copper support resisting to wear and tear and heat and with a series of pressing plates in brass alloy that lock the pieces. Pieces with thickness from 0.5 up to 4 mm and lengths which may go from 200 to 3000 mm are joined together thanks to the sturdiness and high precision of the mechanical processing. The AUTOMATIC BSL series is suitable for welding pipes by an automatic process of locking the edges of the piece. An adapting cradle, moved by pneumatic or motorized motion, locks the tube aligning the edges and obtaining a very good repetitiveness in big lots of production.

Automatic line for bending and welding of stainless steel pipes, maximum length of 1000mm and diameters between 130mm and 240mm. The equipment is composed of: an automatic interlocking bench of the bending unit with an identification system of sheet length, allowing the selfadjustment of the equipment; a two-roll bending unit; a pick-up unit to take the piece to the welding area; a longitudinal welding seamer where operations of gauging, alignment of the tube and plasma welding take place; an automatic unloading bench.