MC - CARTESIAN AXIS MANIPULATORS

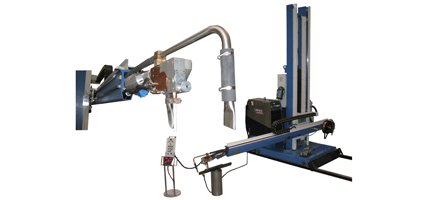

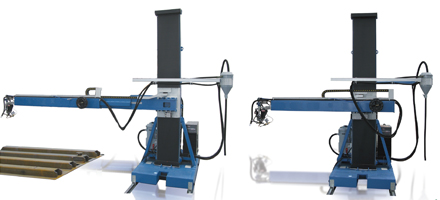

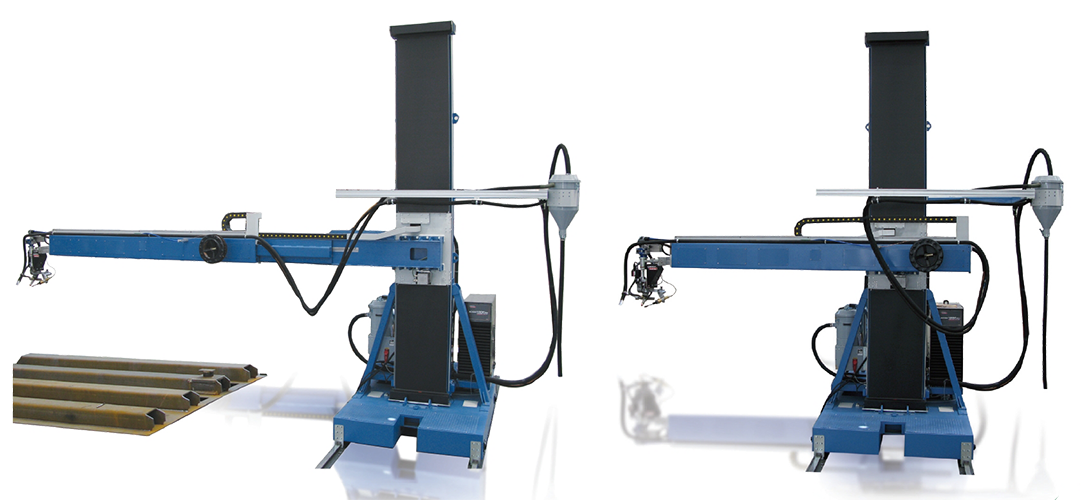

MC - CARTESIAN AXIS MANIPULATORS MC series Columns and Boom Welding Manipulators are planned to carry out automatic welding by the linear axis of the boom. The strong structure makes any movement of the boom very easy to accomplish, even according to the welding process (TIG-PLASMA-MIG-SUBMERGED ARC)

Three different solutions are available:

• Fixed basement with fixing systems to the floor

• Motorized basement settled on a variable speed tracks, moved by a brushless gear motor

• Motorized basement on fixed structure at variable speed, moved by a brushless gear motor.

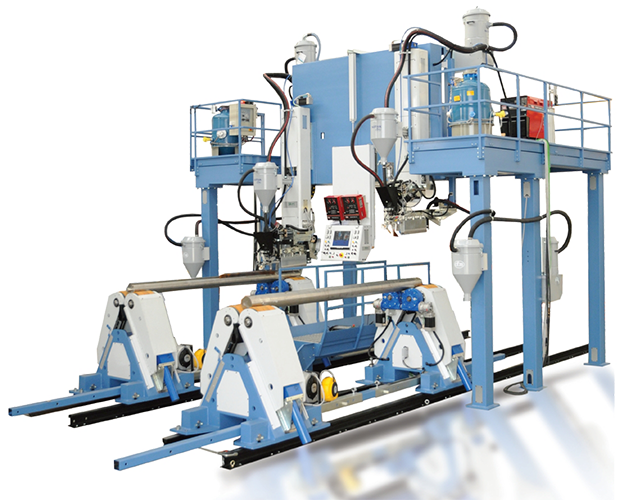

This is an equipment for the flat welding of iron section bars using the process in submerged arc Twin Arc. The manipulator is mounted on rails and a receding beam reduces the overall dimensions on the rear area during the welding. By the technology Twin Arc it’s possible to make the maximum use of the equipment reaching high welding speeds and very good seams. The machine is equipped with a proportional electronic sewing probe.

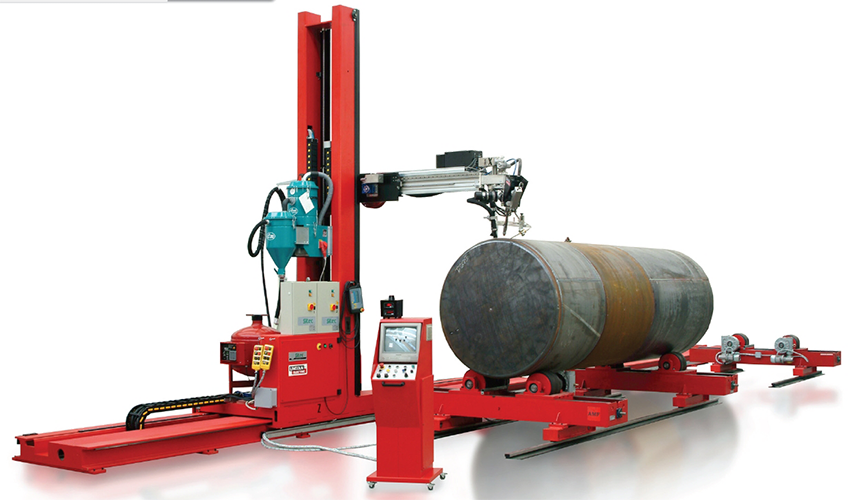

This equipment is for circumference welding of curved bottoms and large tubes by means of a SUBMERGED ARC procedure. It is made up of a base with a linear motion system for translation of the Cartesian manipulator over a length of 18000 mm. The front part of the aluminium bar has a submerged arc torch able to rotate to adjust to the piece to be welded. This rotation movement is effected by two pairs of 20000kg motor-run rollers which may work on the same piece on an electrical axis and also individually, which makes it possible to obtain two working stations. The proper positioning of the submerged arc torch on the welding joint is made possible by an electronic proportional probe of our production and a small colour video camera.