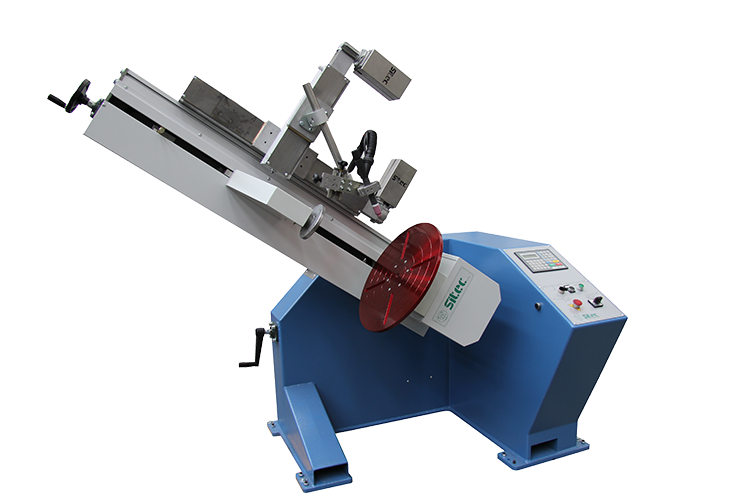

ITVP - TILTING LATHES

ITVP series equipments are tiltable lathes for the circumference welding on pipes, flanges, sleeves… It’s made of a fixed base, complete with electric panel and controls on board, and by a beam that can be tilted both manually (by handwheel) and hydraulically. A tailstock placed on the beam moves pneumatically and is manually adjusted all along the beam by a handwheel which is placed at the end of the beam itself. The rotation axis is composed of a bearing hub, of a plate where to place the particular to be welded or the toolings, of a rotating mass 500A and of a D.C. gearmotor or a Brushless motor controlled by NC. On the basic version it’s possible to apply to a driven axis a pneumatic arm for torch clearing, including a torch support and a maximum of three axes managed by NC.

Equipment with tilting lathe, heavy series, for MIG welding of flanges on steel tubes with a maximum diameter of 600 mm and of a maximum length of 800 mm. The unit is composed of a fixed base and a tilting beam with hydraulic system, of a pneumatic mandrel to lock the tube and its rotation and of a moving tailstock. The torch is moved by two Cartesian axes placed besides the beam.

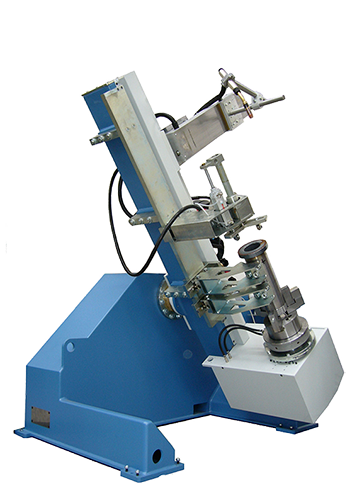

Equipment with inclinable lathe for copper-steel and copper-copper brazing of pieces with 200mm and 400mm diameters. This equipment is used for circumference welding of air spaces inside condensation boilers and is equipped with a pneumatic self-centring fixing spindle of our construction and with a mechanical feeler for proper positioning of the torch over the area where welding is to take place.