ESP - EXPANDER SYSTEMS

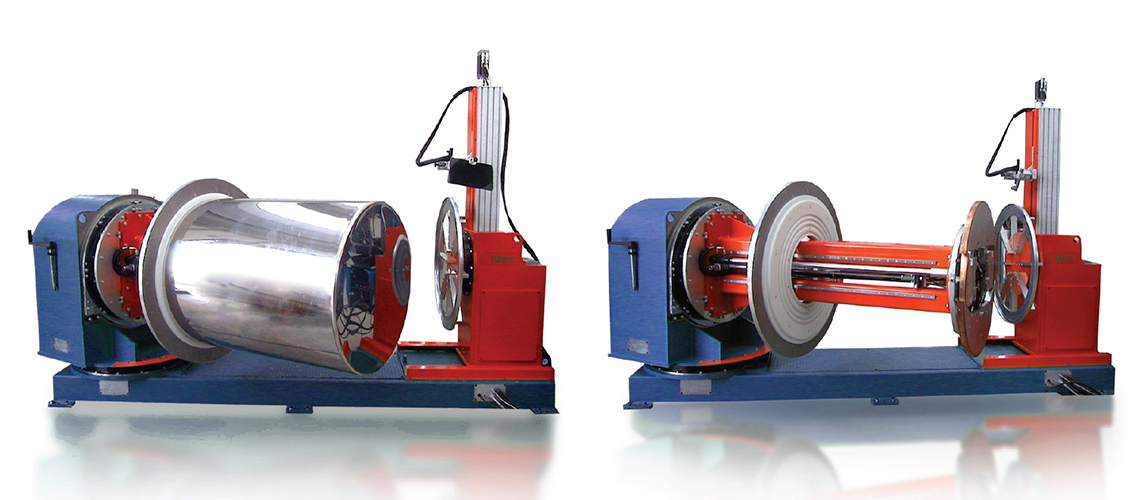

ESP series equipments are realized to carry out a circumference welding of bottoms on tubes of different thickness and materials. On these machines we apply a hydraulic expansion system composed of 4 inner and interchangeable sectors for different diameters, in order to support the head-to-head welding and lock the bottom of the tube. All the expanders are made of an alloyed and hardened material to obtain a very little wear in time and a very good heat removal.

Internal expansion equipment by external circumference welding catering for diameters ranging between 200mm and 1100mm and thicknesses between 0.5 and 3mm of pressed bottoms on stainless steel tubes using a TIG procedure. The basic operation consists in locking both the bottom and the tube being used on a special copper expander which adheres all around the circumference. In this phase, while the pieces are properly locked in position and gauged to adapt to the nominal diameter, they are made to rotate and the circumference welding takes place. Once the welding has been completed, the welding head rotates to facilitate unloading and release of the finished piece after the centre has withdrawn.

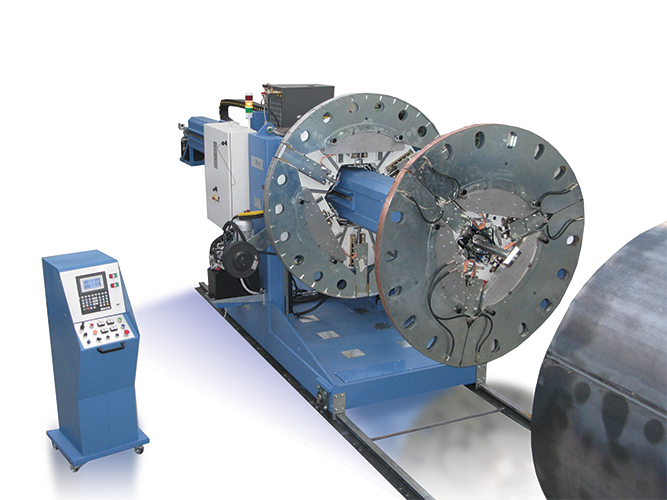

Expander system for MIG welding of bottoms on tanks of diameters between 1200 mm and 2000 mm, thickness from 2 mm to 5 mm and maximum length of 5mt. The line is composed of a trailer-mounted structure, a fixed expander and a moving beam with an expander at its extremity in order to work different sizes of tanks. The machine is equipped with two expanders complete with a hydraulic system locking the bottom at the tank.