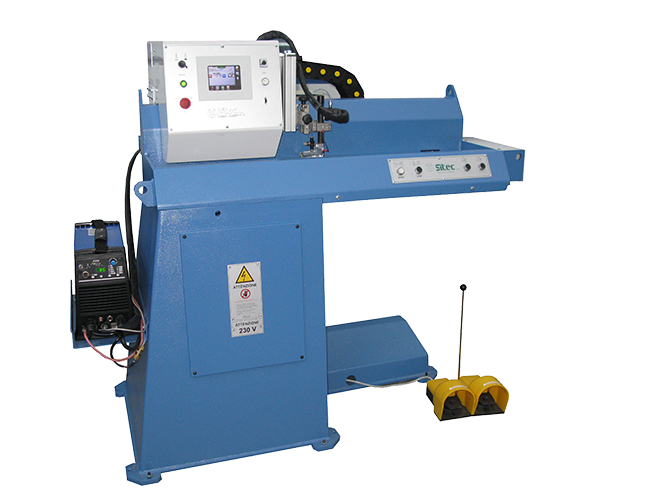

BSL – LONGITUDINAL WELDING EQUIPMENT

Standard equipments for longitudinal welding of tubes and sheets with different welding process: Tig, Plasma, Laser, Mig-Mag and Submerged Arc. They are equipped with a copper support resisting to wear and tear and heat and with a series of pressing plates in brass alloy that lock the pieces. Pieces with thickness from 0.5 up to 10 mm and lengths which may go from 30 to 8000 mm are joined together thanks to the sturdiness and high precision of the mechanical processing. The BSL STANDARD series is equipped with a supporting rod in copper settled a fixed height from the ground and it may have a lifting unit being operated by rollers to facilitate preliminary closure and loading/unloading of the pieces.

Standard equipments for longitudinal welding of tubes and sheets with different welding process: Tig, Plasma, Laser, Mig-Mag and Submerged Arc. They are equipped with a copper support resisting to wear and tear and heat and with a series of pressing plates in brass alloy that lock the pieces. Pieces with thickness from 0.5 up to 10 mm and lengths which may go from 30 to 3000 mm are joined together thanks to the sturdiness and high precision of the mechanical processing. The BSL STANDARD series is equipped with a supporting rod in copper settled a fixed height from the ground and it may have a lifting unit being operated by rollers to facilitate preliminary closure and loading/unloading of the pieces.